During the Summer of 2022 I had an amazing opportunity to intern at Lightship RV, an awesome bay-area start-up by Tesla Alumni, designing and building an all-electric RV! I worked as a mechanical design engineering intern, and I was tasked with the complete design, manufacturing, assembly and testing of the cooling system for their first vehicle prototype (the power demonstration unit).

The goal was speed. It had to be done fast, ready for testing and another round of fund-raising (start-ups aren’t cheap), and it had to look great.

While I can’t disclose many details of the work I did, as it was project sensitive, I can share some pictures that detail the design work I went through, and the final working assembly that I fabricated by hand!

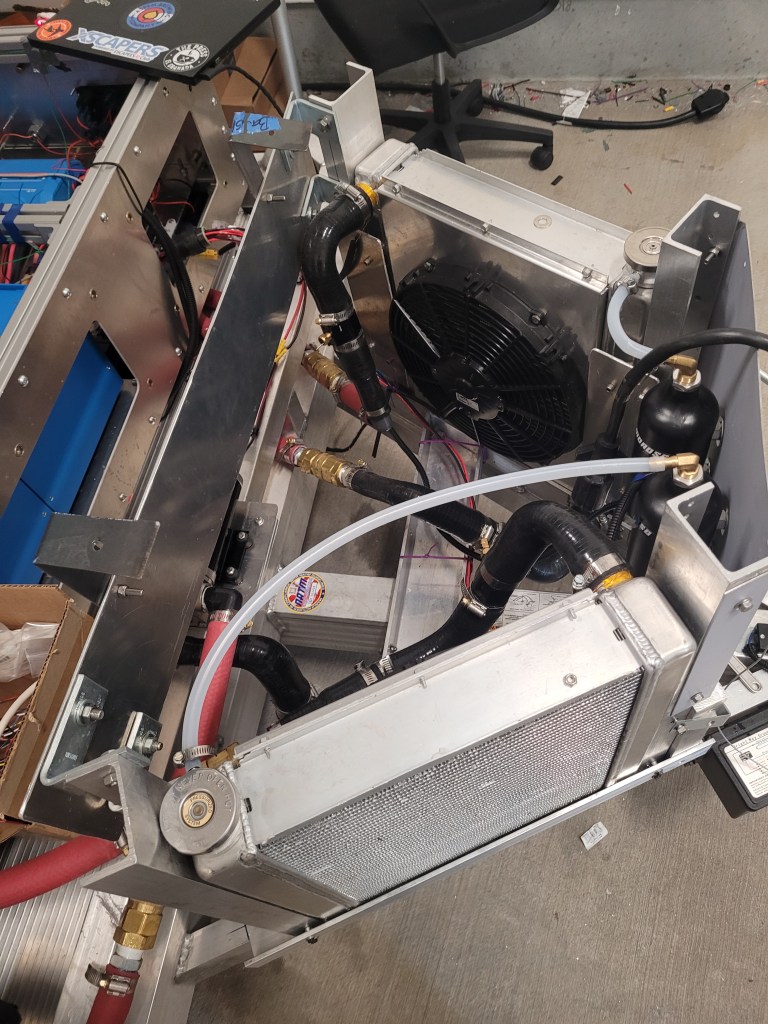

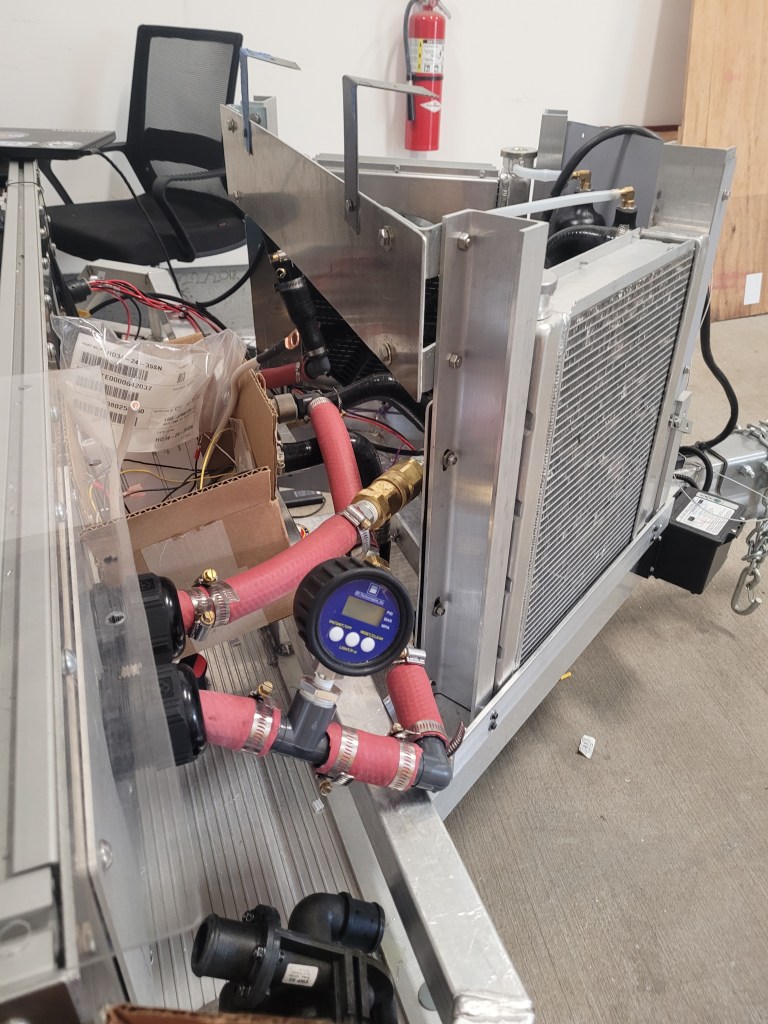

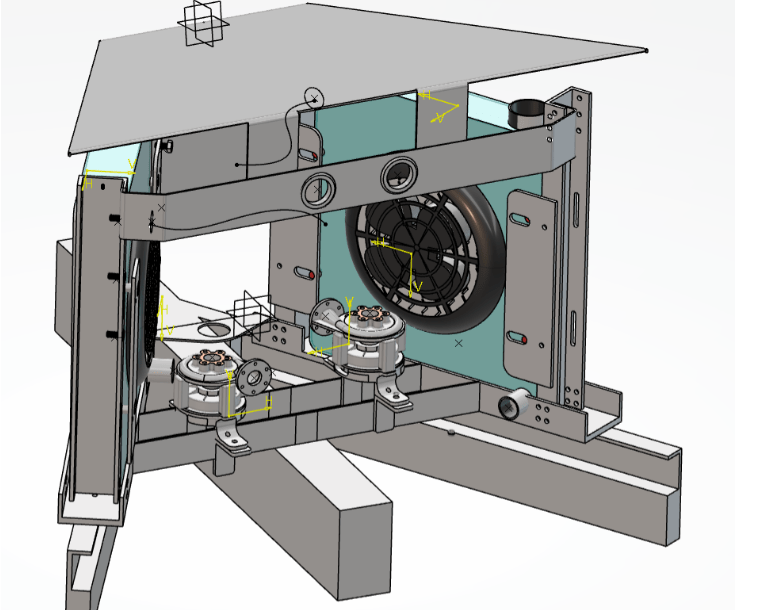

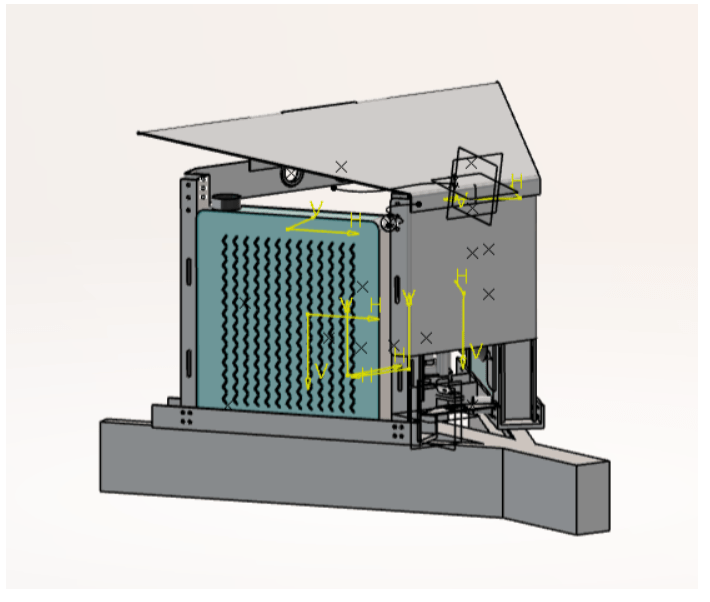

I chose radiators and pumps to run coolant through two seperate loops, cooling the batteries and the high voltage electronics. I then designed the frame to hold all the components together using Catia, which was a lot of sheet metal modeling.

Once that was complete (roughly 3 weeks), I ordered metal to fabricate all the mounting components using our in-house machine shop where I became quite handy with the manual mill (amidst other fun tools: bandsaws, angle grinders, brakes and more!), and all the tubing and connectors to set up the cooling system.

Finally I assembled the system, routed all the hose line, creating sealing and panel pass-throughs, mounted all components (I created custom mounts for the pumps and radiators), wired the electronics and finally began testing and characterizing the flow rates of the system.