For a design challenge, I created a robotic leg using capstan drives and pulleys in 2 days.

Requirements

Specifications:

- Extended leg length 0.5m

- Hip and knee continuous torque of 7Nm at 40 rad/s

- Maximize actuator torque density: motor, gearbox, housing

- Minimize leg inertia (distal mass and total mass)

- Off the shelf fastners and components where possible

- Cost – design for cost and manufacturability

- Any type of fabrication method

- High Volume, production capable design

Design Goals

The problem is incredibly open ended and has many possible variations to a solution. My focus will be on distal weight, inertia and focusing on quick motion for running and jumping

This means:

- Potentially using composites

- Using lightweight, high strength alloys

- One actuator for both joints

As a secondary goal, reducing cost and improving power transmission from the motors

- Potentially using a single motor to reduce overall weight

Design Inspiration

Multiple linkage mechanisms could be used to perform the motion, however most seem to be four / five bar linkages

There is potential to use a Jansen mechanism with a single motor, however that increases distal weight and only has one motion, cannot be used for jumping

Deciding the dimensions of the legs, as well as the angles of rotation of both legs depends on the types of gear and actuation mechanism

Generally, the closer the knee linkage is to the hip joint, the better the positional accuracy and less torque. The further away the knee linkage is, the higher the linear speed and strain on actuation system.

Starting from 0.25m, 0.25m for a total length, and optimizing for force, spring and torque from there

Leg Design Ideas

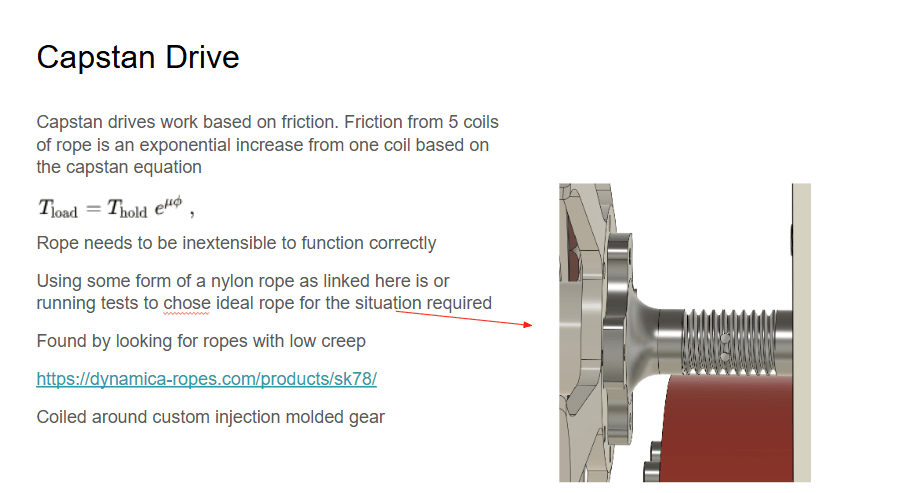

Make joint 1 (thigh) capstan drive driven

Direct gear reduction

Low cost components using nylon or kevlar / polymer wire

Backdriveable and no backlash

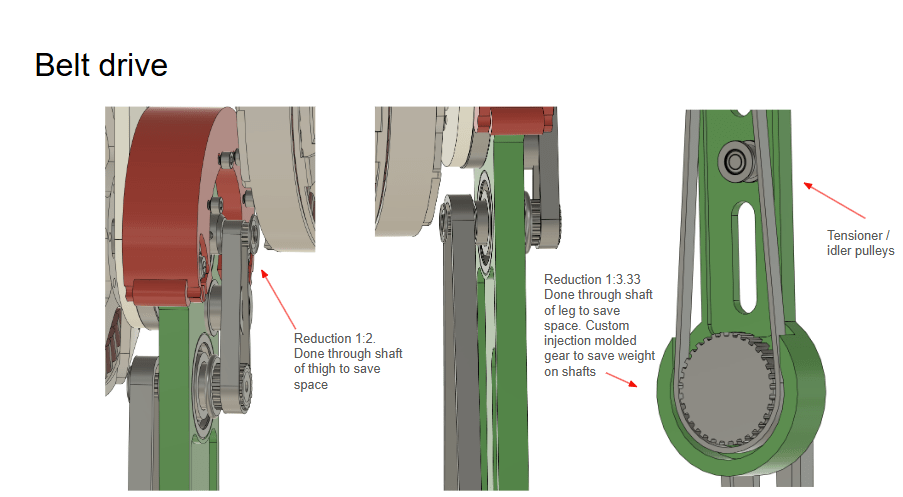

Make joint 2 (knee) belt drive driven

Multiple gear reductions

Low cost and high volume

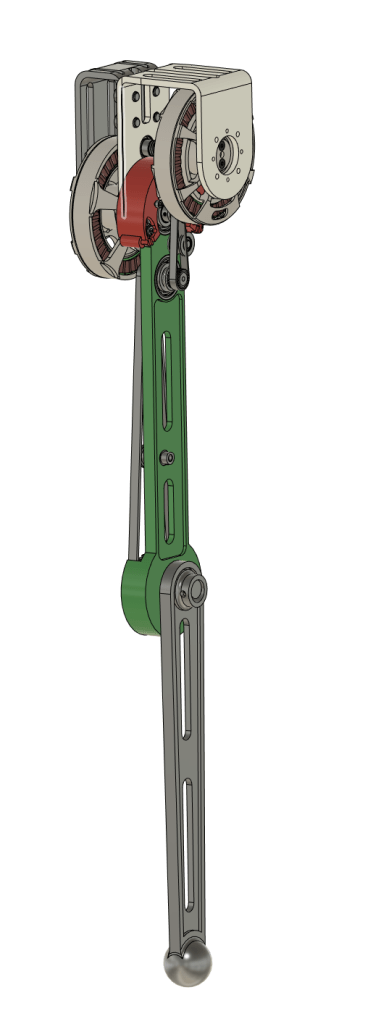

Motor Positioning

Since knee joint is going to be belt driven the motor has to reside on the first link, belts cannot increase in length.

Motors positioned as close together as possible

Bolt together machinable / sheet metal stamped housing units

Top motor drives thigh and lower motor drives knee

Design Points